VVV MOST > PRODUCTS & SERVICES > Magnetic Separators > Magnetic Drum Separator MBS

Magnetic Drum Separator MBS

|

Simple and reliable solution for separating magnetic particles from bulk materials.

Magnetic drum separators MBS are designed for the continuous separation of foreign magnetic particles from dry granular materials of small granularity. They can be applied wherever there is a risk of damage or undesirable influence on the following technological processes due to the presence of magnetic particles in the base material, or where the separation of magnetic and non-magnetic particles is directly part of the technology.

It is a solution suitable for example in the environment of recycling operations, foundries, ceramics, power and fuel, glassworks and others. The separator works on the principle of attraction of the magnetic field generated by the system of high-intensity permanent magnets fixed in the rotating drum shell.

Advantages: • Easy installation • High separation efficiency • Maintenance-free operation • High operational reliability • High magnet magnet system • 20 years of magnet efficiency guarantee • Wide range of dimensions

ORMAKON magnets have a non-homogeneous magnetic orientation that concentrates the magnetic flux and significantly increases the maximum magnetic field induction values in the functional pole. In this way, higher efficiency can be achieved than with homogeneously oriented anisotropic magnets.

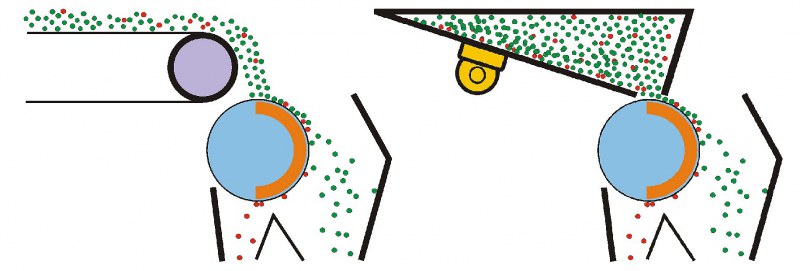

The material flowing through the drum shell is exposed to the magnetic field, and the magnetic particles are attracted by the field to the shell. The release of the drum will take place outside the magnetic field of the magnet. Separators are installed mostly under the conveyor drive drum or below the hopper edge of the vibratory tray or hopper.

The use of these new magnets makes it possible to increase their technical parameters such as force magnetic effects, magnetic induction, power, energy saving and miniaturization. |

|||||

|

|

|||||

|

The values in the table are standardized series. Separators may also be supplied, if required, in other length dimensions and with modified end shafts for storing. We always recommend using the MBS separator to consult with the vendor. |

|||||

|

|

|||||

|

|||||

|

.jpg)