VVV MOST > PRODUCTS & SERVICES > Magnetic Separators > Permanent Sorting Magnet PTM

Permanent Sorting Magnet PTM

|

Solid permanent sorting magnets are used primarily to eliminate magnetic impurities that are contained in bulk materials.

Permanent PTM sorting magnets are also used for cleaning loose pieces of material such as: crushed stone, grain, sugar, coffee, coal, wood cuttings, brick waste etc.

Permanent PTM sorting magnets should be used for low-pollution products.

In case of loose materials with a high content of magnetic impurities, the device would require frequent manual cleaning. For this case, it is preferable to use a separator with automatic material delivery.

The quality of the separation also depends on the belt speed, product type, grain size, type and form of the extracted parts. Magnets are produced in any size and four basic heights, for use with the maximum distance of the separator from the belt for a distance of up to 150, 200, 250 and 300 mm.

Advantages: • Easy installation • High separation efficiency • Maintenance-free operation • High operational reliability • High magnet intensity system • 20 years of magnet efficiency guarantee • Wide range of dimensions

ORMAKON magnets have a non-homogeneous magnetic orientation that concentrates the magnetic flux and significantly increases the maximum magnetic field induction values in the functional pole. In this way, higher efficiency can be achieved than with homogeneously oriented anisotropic magnets.

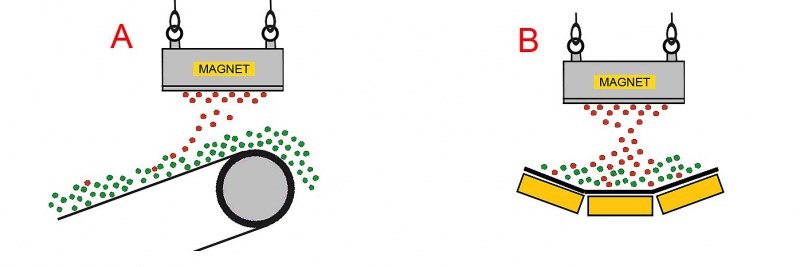

Permanent PTM sorting magnets can be installed either above the end drum (Figure A) or above the conveyor (Figure B). In both cases, it is necessary to ensure the non-magnetic properties of all parts under the magnet (separator) to avoid magnetic field interference. |

|||||

|

|

|||||

|

|||||

|