VVV MOST > PRODUCTS & SERVICES > Development, Research & Measurement Technology > Vulcanizing Press Machine TVJ

Vulcanizing Press Machine TVJ

|

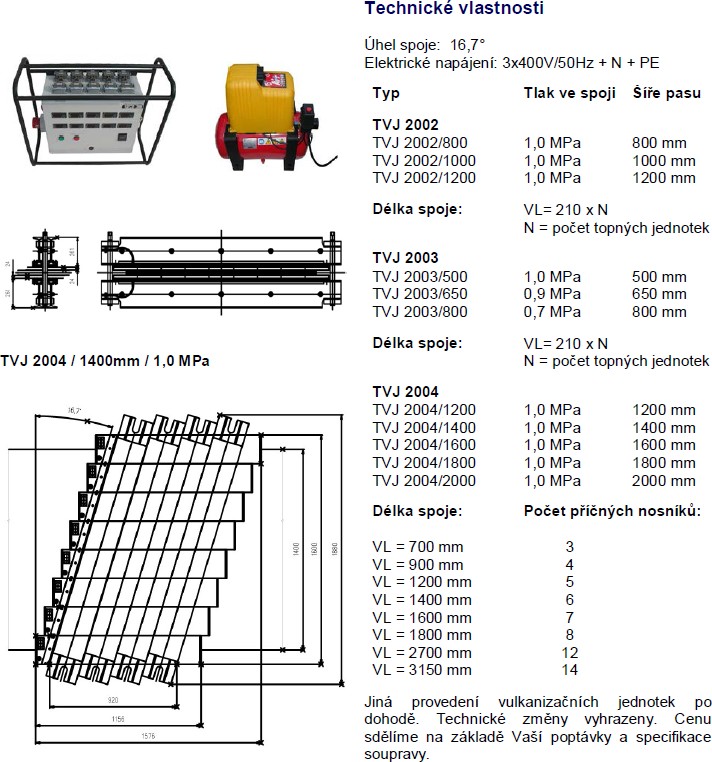

The heat-vulcanising unit TVJ-2002 is a portable modular vulcanizing device designed for jointing conveyor belts. The vulcanization ensures a uniform temperature with a tolerance of +/- 2 ° C and a uniform pressure across the surface according to the preset values. The TVJ 2002 vulcanization press is manufactured in widths of 500 - 1400 mm and can be equipped with cooling if desired. In contrast to conventional vulcanization presses, the beam with the heating plate is one block, including a pressure bag in the upper block. Pressure is induced by air. The whole set is characterized by very low weight.

The complete vulcanization unit is an essential part of the whole set. It consists of the upper heating block, the bottom heating block and the tensioning screws. The heating top block is a compact unit consisting of a heating plate, a push rail and a beam forming the frame. The heating lower block is a compact unit consisting of a heating plate and a beam forming a frame. Both beams are pulled down by tightening screws, which form an integral part of the complete vulcanization unit. The beams are made of pressed aluminum alloy profiles. The pressure bar is equipped with a pneumatic push rod that expands the beam and the heating plate through thermal insulation. This creates an even pressure across the conveyor belt. Pressure bellows are connected to the compressor distributor by means of pressure hoses fitted with quick couplings. The heating plates are also molded profiles of aluminum alloy. The plates are fitted with heating elements and each plate is equipped with a temperature sensor. To the control box, the heating plates are connected by means of movable plugs. This unit has a width of 200 millimeters, and by folding these basic units together, it is possible to create an arbitrary joint length graded by 200 millimeters each.

The control box is designed to control the temperature and power of the individual upper and lower heating blocks. At the same time it is equipped with a compressor supply socket (pressure air source for vulcanization pressure). The individual force elements are located on the inner panel. On the left side of the cabinet there is a 63 A / 5 p fixed inlet (version of the 6 pairs of heating units is equipped with a 125 A / 5p lead), production plate and main switch with yellow panel and red arrow, connectors for connection are installed on the upper side of the cabinet individual heating units, the compressor drawer on the right side of the cabinet. In the front door of the cabinet are installed control and control elements. In the upper part of the door are placed controllers for temperature control of individual heating plates.

Under the controllers there is a digital time relay with a time-setting display and two trigger buttons (green) and a premature end (red) vulcanization cycle. The control unit is stored in a plastic box. At the request of the customer, the box may be provided with a protective tubular frame.

If you are interested in our services, please do not hesitate to contact the person or send a request to E-mail. |

|||||||

|

|

|||||||

|

|

|||||||